Foils on printed items are cost-effective to make your package stand out. Especially utilizing foils may impart a shiny or golden design to your project. It’s one of the few ways to include “genuine” gold and silver in your plan. It’s trendy when looking for a more elegant appearance so that it may be a handwritten letter or a magazine. Because hot-foil printing is a ubiquitous printing process, you can usually find it on your items, regardless of whatever you’re shopping. For your business, you can check out the aluminum foil manufacturer. We’ll go through how it performs and where the approach is most often utilized in this post.

What is hot-foil printing, and how does it work?

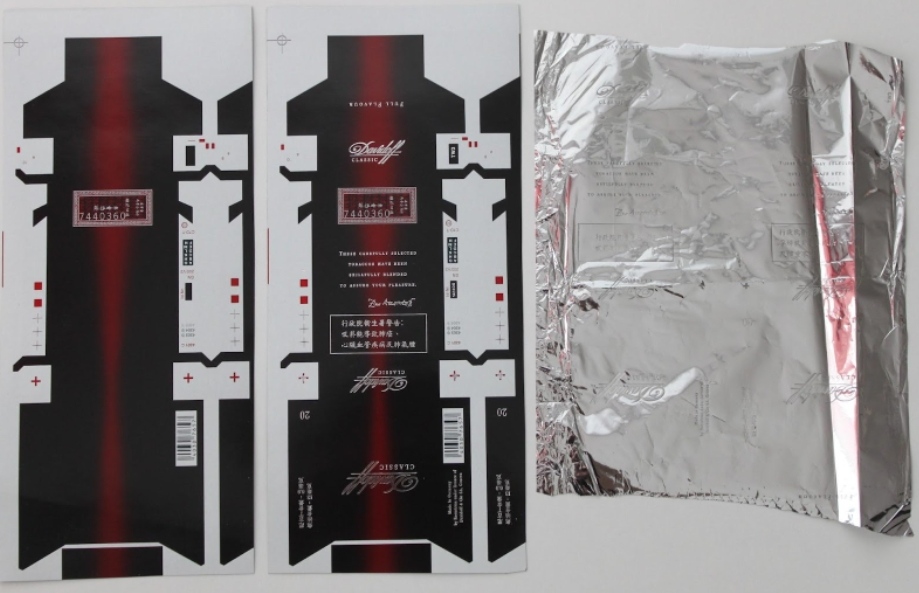

So let’s get the terminology of hot-foil printing precise first. Hot-foil printing, often known as hot-foil stamping or foil printing, is a kind of hot-foil printing. This printing process involves putting metallic or colored foil to the exterior of printed items to provide a unique finish. It may be used to achieve various effects, including metallic, matte, and glossy effects.

What are the steps in the procedure?

There are two methods for achieving the desired result when it comes to foil stamping. Traditional foil printing is the most widely used method. However, digital foil printing is rapidly gaining popularity, which is less expensive than conventional foil printing. But, of course, we’ll go through both procedures.

Foil printing history

Produce the hot foil in the printing machines employ the foiling dye, a metal plate with the pattern you want to be foiled on the item engraved in by photo-etching. Almost any design may be created with the die. The heated foil is then put to the dying and heated until it reaches the desired temperature. The foil is then pressed against the printing surface by the dye, causing the foil to adhere and integrate with the object’s surface.

Limepack production

Because the procedures employ one dye for each color, if you wish to use various colors with the hot-foil method, you’ll need to run the process many times and create multiple dying.

Foil printing with digital technology

Regarding what the foil will appear when printed, computerized foil printing is quite comparable to conventional foil printing. The procedure works by digitally printing the picture onto a unique foil that may be utilized on the surface. This implies that the computerized foil printing approach does not need the creation of a dye for each color used in the hot-foil process.

Varieties of foil

The kind of foil that was used procedure impacts the final polish of the surface. Metalized foil is the most often used because it has a lustrous finish and may be used with gold and silver foils. Multicolor foil and scratch-off aluminum are two more types of foil that are more well-known. The colored foil is used on both plastic and paper, and it is what imparts a texturized appearance to shiny or matte surfaces. Lottery tickets and passcode cards are the most common uses for scratch-off foil. As the name indicates, the process creates a tiny shell that is easier to scratch.

What is the most common application?

Cards, magazines, and business cards are among the items that employ the foil printing process. Although the method may be used on various materials and is not limited to printing on paper, it is most often employed for printed on paper. It is frequently used with laminating the print because it provides a more luxury touch. A business owner also collaborates with a handful of companies of the laminated aluminum foil supplier that offer hot-foil engraving on disposable cups and beverage cups.

Application in Other Industries

Food and drink, cosmetics, electronics, banknotes, business cards, greeting cards, and artwork are among the industries that employ hot foil stamping.

The significance of decorations like hot foil printing is undeniable. According to research by the Foil & Specialty Effects Association (FSEA), hot foil stamping and other comparable upgrades on product packaging may help draw customer attention quicker and maintain it longer than standard packaging. Another research on single record coffee packaging found that gold foil packaging attracted the attention of study participants 2.5 times faster than the standard packaging.

It’s not just about appearances. Anti-counterfeiting hot foil stamping capabilities are employed in various industries, including medicines and innovations such as cellular devices.

The mark of long-term viability

Durability is becoming an ever more important goal for brand owners, and it may serve as a point of difference in and of itself. Many people believe that foil-decorated packaging is unrecyclable and hence unsustainable. Yet, research conducted by the FSEA on the reusability of foil-decorated material and board verified the recyclability of packaged items adorned using typical hot stamp foil methods.

Furthermore, the research discovered neither warm nor cold foil-decorated items would cause issues that would make the elegant paper products unrecyclable.

What is the future of hot foil stamping?

For well over a century, hot foil stamping has existed in some form or another. The method hasn’t changed much in that period, but technology has progressed, allowing producers to be more efficient.

A hot foil stamper may be a stand-alone machine, or it can be used with a printing press and other appliances. While most high-speed hot foil stampers are sheet-fed, others are web-fed.

In the end, While hot foil stamping isn’t the only way to create unique packaging, using metal inks, varnishes, and aluminum foil are a few examples of other fantastic alternatives. But it seems to be a continuously developing industry to stay long in the packaging market. The effect will always appeal to consumers on the packaging and give a visual shortcut to the product’s quality.